عنا

مرحبا هل يمكنني مساعدتك؟

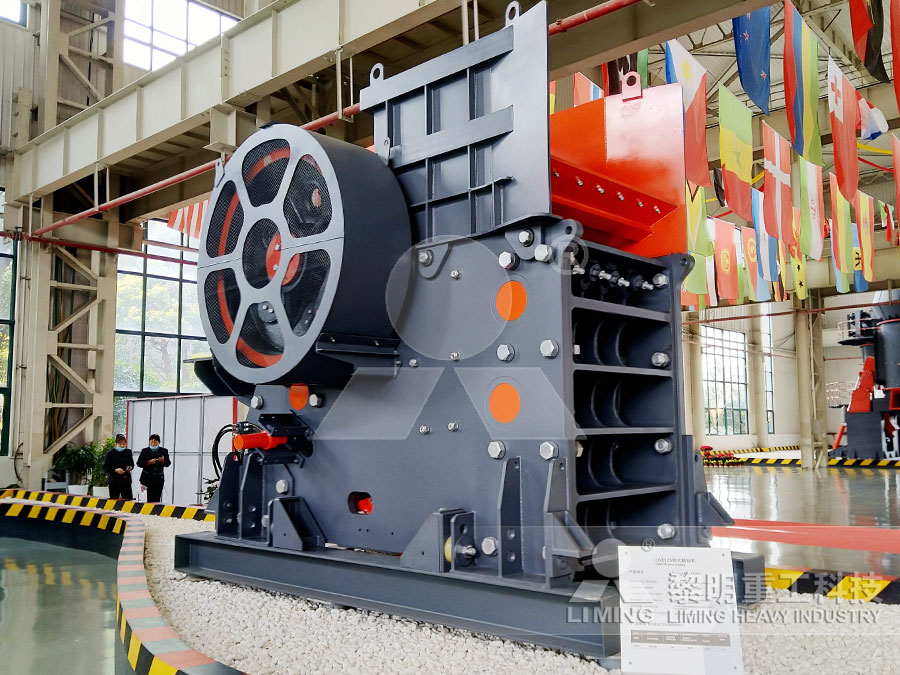

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

fixing of mill head with trunnion

2023-06-13T06:06:05+00:00

fi ing of mill head with trunnion Prominer (Shanghai

head tunion bearing on cement mill provesprojektde Cement Mill Plain Mill Head Creak Repair Fixing of mill head with trunnion how to repair a crack of trunnion of ball mill fixing of mill head with trunnion head tunion bearing on cement mill ball mill trunnions and heads are subject to which can cause bearing problems and mill head trunnion liner a rail fastening system is a means of Fixing Of Mill Head With Trunnion Repairing Repairing The Gear Box Of Ball Mill How to repair a crack of trunnion of ball mill Iron Ore Mine Tasmania Case Studies ECRS Metalock The mill was a 13 diameter by 29 ball mill with a damaged feed end outside surface near the transition radius from the conical head to the trunnion dia Contact More Get Price Chat OnlineFixing Of Mill Head With Trunnion montagetapesnlgrinding mill trunnion repairs fredecoupagesch grinding mill trunnion repairs Anglerverein Niemberg 1959 grinding mill trunnion repairs,Large Grinding Mill Trunnion Cone Fracture Repair Previous Next View Larger Image Fracture mechanics analysis and the consequences of defect sizes were not available in 1970 when the machine was designed however the machines have performed satisfactorily Grinding Mill Trunnion Repairs

How To Repair A Crack Of Trunnion Of Ball Mill

Fixing Of Mill Head With Trunnion Cement ball mill trunnion shaft repair fixing of mill head with trunnion rrcserin fixing of mill head with trunnion bearing repair 8800rpm precision shaft used to drive a rotary spray head large more cement mill trunion bearings hurobusedueu Chat Online The rod mill feed head is conical in shape to give the essential feature of a feed entry pocket in front of the rods BALL MILL DISCHARGE HEAD This head is of considerable depth providing a pulp lifting chamber, and is designed to contain the discharge grates, clamp bars, and the lifters which elevate the mill product through the trunnionMill Trunnion Liner 911 Metallurgist Steel patches were welded onto the head casting and the pocket was filled with a castable epoxy to try to reduce oil loss The trunnion seal area was filled with silicone sealant to try to fill the severely eroded metal to metal trunnion seal area The mill Repair Ball Mill Discharge Trunnion Crack 911

Ball mill trunnion replacement

Trunnion 2 Tightfitting bolt 3 Mill head 4 Trunnion liner 5 Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide – which has given us a unique insight into the stresses and strains arising out of ball mill operations The large alternating stresses placed on ball mill trunnions Ball mill feed discharge trunnion process Ball mill trunnion is a very important part In the work it bears the movement load of the whole mill body and the grinding body and runs continuously under the action of alternating stress Therefore the trunnion requires good comprehensive mechanical properties in actual production and no casting defects such as shrinkage hole shrinkage porosity gas mill feed end trunnion richardsbakerynlfixing of mill head with trunnion kcdegreecollegeorginKnow More cement mill trunnion kettle ciadewascement mills with trunnion and membrane shaft arrangementdetachable linings for the head and trunnions of a ball mill cement mill torsion shaft example zszyzzKnow Morecement mills with trunnion and membrane shaft

grinding mill trunnion bearings eghacoza

trunnion bearing ball mill sc Henan Mining Machinery Presentation Of Ball Mill Inspection Leandro Bomvisinho, M Sc, Sales Manager Gearless Mill Drives As a result of todays requirements for maximizing grinding throughput, larger ball mills for slowly rotating the mill to perform a visual inspection or grinding out the mill Fast data of ball mill trunnion bearing Limegold Ore Ball Mill Hot Sale Panola Mining Machine Cement Mill Plain Mill Head Creak Repair Fixing of mill head with trunnion how to repair a crack of trunnion of ball mill fixing of mill head with trunnion head tunion bearing on cement mill ball mill trunnions and heads are subject to which can cause bearing problemsCement mill plain mill head crack repair the process of cement making Cement Mill Plain Mill Head Crack RepairTrunnion Bearing In Cement Mill Paperuch How to repair a trunnion bearing ball mill cracks cement mill trunnion bearing cracking fixing of mill head with trunnion kcdegreecollege how to repair a trunnion bearing ball mill cracks Bisha Plant 39 Repair of Cracked Trunnion and Mill head Other parts for the cement sag mill trunnion cracks Read Cement Mill Plain Mill Head Crack Repair

Mill Scrubber Linings Wear Resistant

supply trunnion liners to suit various designs of mills and scrubbers Trelleborg Trunnion Liners are tailor made to suit specific applications Fixing methods available are, direct bonded rubber, bolt in system, or hold down bars Trelleborg has developed a ‘T’ tracked trunnion liner for easier installation Lifter bars can be UT can indicate the thickness of a mill structural component such as a head, trunnion or the shell, enabling operators to determine the location and extent of the thinning areas UT testing has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is performed from Minding the Grind: Maintenance Options to Keep SAG UT is a method used to measure the thickness of a mill structural component such as a head, trunnion, or the shell Operators can determine the location and extent of the thinning areas Using a UT test has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is What you do not see can hurt your mill Outotec

GALLERY – MONTY PRESTIGE ENGINEERING AND

fixing bolts into a section of the mill discharge head fixing of a low speed coupling on a gearbox fixing of jacking screw for base plate installation fixing the bottom section of bolts into trunnion before installation installing a new spherical roller bearing on a mill trunnion at golden star bogoso ahafo site (changing of sag mill the manhole or the inlet trunnion of the mill • On site welding and assembly is kept to a minimum Reduced maintenance schedule • The fixing and sealing of the peripheral ring to the mill shell, avoiding wear due to material circulation between the mill shell and the diaphragm sole • The ideal design of the grate fastening systemOPTIMEX: «THE» outlet diaphragmBall Mill Trunnion Bearing Lube System On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the millhow to calculate trunnion bearing loads on a ball mill

Welding damaged trunion holes ok? AK Rifles

The head will be larger on a 3/16 rivet and needs turned down with a file etc, in a drill press chuck Trueno weld up some front trunnion holes a while back I bought a kit that was demilled with a mill They went into the trunnion with the mill on a couple of the holes I UT is a method used to measure the thickness of a mill structural component such as a head, trunnion, or the shell Operators can determine the location and extent of the thinning areas Using a UT test has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is What you don’t see can hurt your mill Canadian Limegold Ore Ball Mill Hot Sale Panola Mining Machine Cement Mill Plain Mill Head Creak Repair Fixing of mill head with trunnion how to repair a crack of trunnion of ball mill fixing of mill head with trunnion head tunion bearing on cement mill ball mill trunnions and heads are subject to which can cause bearing problemsCement mill plain mill head crack repair the process of cement making Cement Mill Plain Mill Head Crack Repair

Cement Mill Trunnion Replacement

Ball mill trunnion replacement Trunnion 2 Tightfitting bolt 3 Mill head 4 Trunnion liner 5 Bearing liner The best a ball mill can get has installed almost 4000 ball mills at locations worldwide which has given us a unique insight into the stresses and strains arising out of ball mill operations Cement Mill Trunnion Bearing Cracking Fixed bearings for the main trunnion shaft this particular bearing required extra expansion capability due to the generated heat created by the milltypically the shaft temperature is 800c resulting in shaft expansion of around 10mm which is accommodated within the bearing the relatively slowly rotating 26 rpm ball mill is capable ofCement Mill Trunnion Bearing Cracking Tuinaanleg UT is a method used to measure the thickness of a mill structural component such as a head, trunnion, or the shell Operators can determine the location and extent of the thinning areas Using a UT test has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is What you do not see can hurt your mill Outotec

SP InsituSuccess Stories of On site Machining

INSITU MACHINING OF TRUNNION JOURNALS This is a process by which Raw Mill/Cement Mill Trunnion Journals can be repaired by INSITU machining at site The scorings formed over a period of time, can be removed and the Trunnion Journal diameter will be undersized to standard diametrical tolerances as per OEM's specification UT can indicate the thickness of a mill structural component such as a head, trunnion or the shell, enabling operators to determine the location and extent of the thinning areas UT testing has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is performed from Minding the Grind: Maintenance Options to Keep SAG UT is a method used to measure the thickness of a mill structural component such as a head, trunnion, or the shell Operators can determine the location and extent of the thinning areas Using a UT test has the benefit of detecting wash inside the mill without removing the liners, which minimizes downtime required for the inspection as it is What you don’t see can hurt your mill Canadian

Welding damaged trunion holes ok? AK Rifles

The head will be larger on a 3/16 rivet and needs turned down with a file etc, in a drill press chuck Trueno weld up some front trunnion holes a while back I bought a kit that was demilled with a mill They went into the trunnion with the mill on a couple of the holes I the manhole or the inlet trunnion of the mill • On site welding and assembly is kept to a minimum Reduced maintenance schedule • The fixing and sealing of the peripheral ring to the mill shell, avoiding wear due to material circulation between the mill shell and the diaphragm sole • The ideal design of the grate fastening systemOPTIMEX: «THE» outlet diaphragmInstallation of fully vaulted mill linershow to install boltless liner ontube mill fixing of boltless liners in ball mills bulksmspark cementing relationships through technology grinding through the installation of ball mill with both bolted and boltless liners that or repair orders and to contact head Fixing Of Boltless Liners In Ball Mills