عنا

مرحبا هل يمكنني مساعدتك؟

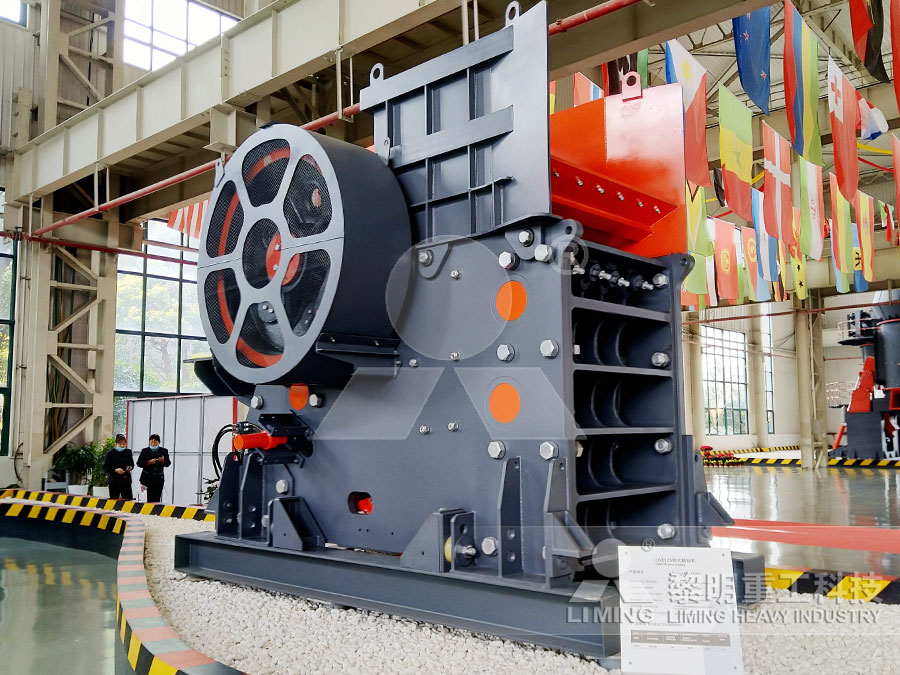

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

nickel production process

2022-11-22T01:11:16+00:00

Nickel Alloy Manufacturing Process

Nickel Alloys Manufacturing Process To make Nickel Alloys , start with the purest available raw materials to achieve the required chemical composition A correct chemical composition is necessary to give uniform and required properties to different alloysThis is achieved by using hydrogen gas under suitable conditions in the autoclaves Nickel powder generated in the autoclaves is then separated from the solution by settling and filtering The nickel powder is dried and then sent on to the powder silo for briquetting or to the powder packaging silo for packaging for customersNickel production Harjavalta Production process Nickel processing, preparation of the metal for use in various products Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance to a unique Nickel processing Britannica

Nickel: smelting, producingMetalpedia

In hydrometallurgical processes, nickel sulfide ores undergo flotation (differential flotation if Ni/Fe ratio is too low) and then smelted After producing the nickel matte, further processing is done via the SherrittGordon process First, copper is removed by adding hydrogen sulfide, leaving a concentrate of only cobalt and nickel Production Process The quality of Phoenix Alloy products is definitely guaranteed due to our strict quality control and management Our alloys are all made in compliance with industrial standards, and we will implement accurate quality control in every technological process from raw materials entering factory to steel smelting, chemical Production Process Shanghai Phoenix Alloy Co, Ltd Nickel pig iron (NPI) production is a new promising process, although it was firstly developed about 50 years ago but it has not been commercially used until some Chinese pig iron producers changed their production methods into NPI production Chinese NPI production wasFERRONICKEL PRODUCTION AND OPERATION

NICKEL PLATING HANDBOOK

nickel production outside China Our mission is to promote and support the use of nickel in appropriate applications NI grows and supports markets for new and electroforming is the process by which nickel is built up by electrodeposition onto a suitable mandrel Production process of ferronickel consists of four main steps Drying: elimination of most or a substantial portion of free moisture content of the nickel oreProduction Process of Ferronickel Miss Rifka Production process of ferronickel consists of four main steps Drying: elimination of most or a substantial portion of free moisture content of the nickel ore Calcinationreduction : elimination of the remainder of the free ore moisture and its crystalline water, preheating of the ore, and reduction of a substantial portion of the nickel and a Production Process of Ferronickel Miss Rifka

Extraction of Nickel Nickel Ore Mining Mining

Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel type JLC Electromet Pvt Ltd, Jaipur, India is a world leading manufacturer exporter of Nickel Alloys and Nickel based speciality alloys in wire, rod, bar, strip and ribbon forms with vertically integrated manufacturing and inhouse research and developemnt facilityManufacturing Process of Nickel Alloys by JLC Zinc + Nickel + Microparticles Coatings: Production Process and Structural Characterization ☆ Author links open overlay panel Zulema A Mahmud a Franco Amelotti a Carlos Serpi a Jorge Maskaric b Martín Mirabal b Norma Mingolo c Liliana Gassa d Paulo Tulio e Gabriel Gordillo fZinc + Nickel + Microparticles Coatings: Production

New largescale production route for synthesis of lithium

New largescale production route for synthesis of lithium nickel manganese cobalt oxide Katja Fröhlich1 Evgeny Legotin1 Frank Bärhold2 Atanaska Trifonova1 Received: 1 February 2017/Revised: 9 May 2017/Accepted: 10 May 2017/Published online: 7 June 2017 # The Author(s) 2017 This article is an open access publication A NICKELIODINESULFUR PROCESS FOR HYDROGEN PRODUCTION S SATO, S SHIMIZU, H NAKAJIMA and Y IKEZOE Japan Atomic Energy Research Institute, Tokaimura, Ibarakiken 31911, Japan (Received for publication 3 June 1982) AbstractA thermochemical hydrogen production process which consists of the following reactions containing nickel, iodine and A nickeliodinesulfur process for hydrogen Direct Nickel has developed a game changing pro cess for extracting nickel from laterite deposits It will position Direct Nickel as one of the lowest cash cost producers in the global nickel industry in the next 5 years The Process offers unparalleled co st efficiency, capital savi ngs and environmental benefitsDirect Nickel Process – Breakthrough Technology

Nickel production from lowiron laterite ores: Process

Nickel production from lowiron laterite ores: Process descriptions @article{Bergman2003NickelPF, title={Nickel production from lowiron laterite ores: Process descriptions}, author={R Bergman}, journal={Cim Bulletin}, year={2003}, volume={96}, pages={127138} } R Bergman; Published 2003; Geology; Cim BulletinA process for the production of nickel sulfate comprising reacting together nickel carbonyl, sulfur dioxide and oxygen at a temperature of about 80° to 150°C to produce reaction products thereof consisting essentially 2 The process as in claim 1 wherein said reaction products are oxidized by aeration in the presence of water to convert the PRODUCTION OF NICKEL SULFATE THE About more than 60% of nickel is consumed for the production of stainless steel, while the rest is used for various industrial purposes such as batteries, electronics, aerospace applications and land based gas turbines ANTAM’s FeNi III Smelter Plant at Pomalaa Ferronickel Production Process To produce ferronickel, saprolite nickel ore PT ANTAM Tbk Nickel

Nickel Mines, Nickel Extraction Process, Nickel

When process coppersulfide nickel ore, collector and frother will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrate Production Process The quality of Phoenix Alloy products is definitely guaranteed due to our strict quality control and management Our alloys are all made in compliance with industrial standards, and we will implement accurate quality control in every technological process from raw materials entering factory to steel smelting, chemical Production Process Shanghai Phoenix Alloy Co, Ltd Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeExtraction of Nickel Nickel Ore Mining Mining

Nickel Metal: It's Properties, History, Production Uses

Production Nickel is primarily extracted from the nickel sulfides pentlandite, pyrrhotite, and millerite, which contain about 1% nickel content, and the ironcontaining lateritic ores limonite and garnierite, which contain about 4% nickel content Nickel ores are mined in 23 countries, while nickel is smelted in 25 different countriesThe present process allows metal salts to be transformed directly into metallic product or into a granular, unfluxed metal oxide that is suitable for electric furnace smelting, or other suitable smelting vessel, to produce, eg, nickel metal for the production of stainless steelsPROCESS FOR PRODUCTION OF NICKEL AND COBALT Production Process of Tungsten Nickel Iron Alloy Tungstennickeliron alloy is an alloy based on tungsten (about 90 to 98%) and added with nickel, iron, copper, or other components, and its specific gravity is generally 170 to 185 It is characterized by high sintering density, good strength, a certain degree of ferromagnetism, good plasticity and machinability, good thermal and electrical Production Process of Tungsten Nickel Iron Alloy ARM

New largescale production route for synthesis of lithium

New largescale production route for synthesis of lithium nickel manganese cobalt oxide Katja Fröhlich1 Evgeny Legotin1 Frank Bärhold2 Atanaska Trifonova1 Received: 1 February 2017/Revised: 9 May 2017/Accepted: 10 May 2017/Published online: 7 June 2017 # The Author(s) 2017 This article is an open access publication A New Process for CoNi Separation – ALTA 2010 2 ABSTRACT A new process has been developed jointly by CSIRO and CESL, for separating cobalt from nickel in an impure leach solution The process uses synergistic solvent extraction (SSX) with commercially available reagents, but in a novel and efficient manner using kinetic factorsA New Process for Cobalt Nickel Separation TeckBHP is transitioning its Nickel West operations in Western Australia (WA) to become a global supplier of nickel sulphate to the battery market But batteries require the highest purity materials to achieve the best electricity storage quality So producing batterygrade nickel often requires new production process technology or improvementsHelping BHP in their journey to produce battery

Environmental Impacts of Nickel Mining and

In a recent analysis, nickel was ranked as the 7 th most damaging metal to human health and ecosystems with the 9 th highest global warming potential, based on production levels from 2008 (3) In 2008, global nickel production was 157 million metric tons and has since grown to an estimated 21 million metric tons in 2017 (4, 5) This trend is