عنا

مرحبا هل يمكنني مساعدتك؟

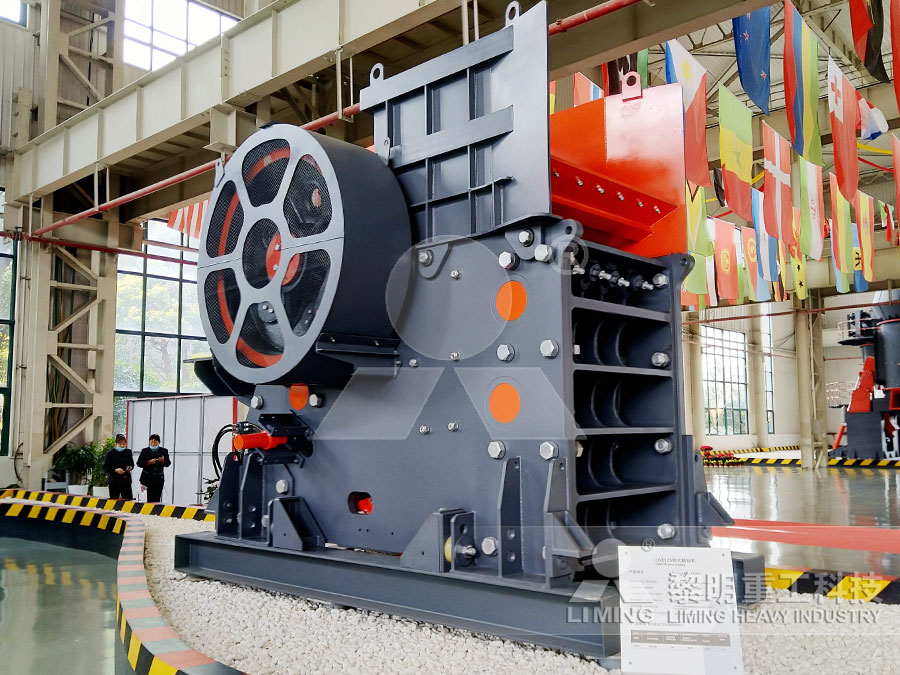

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

process of milling of iron ore

2021-10-01T04:10:14+00:00

iron ore milling process prioratcalcabre

iron ore milling process autogenous grinding iron ore16 nov 2018 processing of crude ore begins in the crushing and stockpiling system ore is delivered to the crusher by 170 ton diesel/electric haulage trucksautogenous grinding iron ore16 nov 2018 processing of crude ore begins in the crushing and stockpiling system ore is delivered to the crusher by 170 ton diesel/electric haulage an Iron Ore Milling Process Mohammad Tabesh, Ebrahim Azimi, Hooman AskariNasab Mining Optimization Laboratory (MOL) University of Alberta, Edmonton, Canada Abstract One of the most common techniques for studying a system’s behaviour, predicting its outputs and anticipating challenges along the way is simulationDiscrete Event Simulation of an Iron Ore Milling Process When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The Six Main Steps of Iron Ore Processing Multotec

Iron Ore Processing,Crushing,Grinding Plant Machine

Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The earliest industrial application of high pressure grinding rolls (HPGR) at comminution was in 1984 in the cement industry Since then, the equipment has been widely applied in mining activities Despite the rapid spread across the industry, several challenges are still present in the equipment’s application, especially considering the complex ore breakage behaviour reported for this processDevelopment of a Novel Grinding Process to Iron Ore The supergenic enriching process, with a low degree of metamorphism produced fragile hematites with small crystals and a high degree of porosity was expected to be a straightforward application of known techniques to construct a mill simulator applicable to ball milling of iron ore has shown a number of unanticipated problemsSimulation of wet ball milling of iron ore at Carajas

process of below 500microne iron ore Solution for

Beneficiation plant of iron ore in india – Stone Crusher Machine The essential reason for using iron ore reserves would be to requires complete mashing to below 500 micron or Iron ore beneficiation plant process Iron ore – Wikipedia, the free encyclopedia Iron ore is the raw Processing of Iranian high sulfur iron ore is problematic in minerals industry The iron ores were studied by the means of polarizing microscopy, chemical analysis, Xray diffraction The study shows that the iron ores have high grade of iron, and complex structures XRD showed that the iron ore consists of metallic minerals such as magnetite with a small amount of hematite and limonite and Process Mineralogy of Iranian High Sulfur Iron Ore Here is an Ancient Gold Ore Milling Process used in China in the 1800s We might use it again after WW3 At the time, 1890, the Author said “There is, of course, nothing for us to learn from this imperfect and rudimentary goldextraction process Gold Milling Process Primitive and Basic 911

Evaluation of sampling systems in iron ore

A variogram for iron grade after primary milling in the concentrating plant is presented in Fig 2 Application of variographic analysis to process data in LKAB iron ore concentrating and pelletizing enabled characterization of sampling systems through the entire value chain (not all sampling system evaluations are shown here) Ore Milling During the 1890s, Edison tried to develop a method for concentrating lowgrade iron ore into highgrade briquettes suitable for use in Eastern steel mills Edison had developed an electromagnetic ore separator in 1880 while working on electric light and power In this device, sand from tailings or crushed rock was poured through a Ore Milling The Edison PapersIron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces The iron ore is separated from the taconite using magnetism Iron Mining Process Minnesota Iron

Manufacturing Process Of Iron Ore Beneficiation

Iron Ore Grinding Mill Grinding Plants For Iron Ore At present the current status of the integrated steel industry and the resource characteristics of Chinas iron ore resources must be continuously improved in Chinas metallurgical ore beneficiation process in order to promote the rapid development of the industry equipment investment in crushing and grinding operations production costsIron ore, coke and lime are added to the top of a furnace Hot air is blown in from the bottom The furnace operates at a high temperature (around 1200°C) Iron ore reacts with carbon/coke to form iron metal and carbon dioxide The iron is tapped off at the bottom of the furnaceCrushing and milling Mining of mineral resources australia iron ore milling process plant for sale australia iron ore milling process plant for sale; The Making of Iron Steel SEAISI The first metallurgical step is to reduce iron ore to metallic iron, a process which is mostly carried out in a blast furnace, using coke as both a fuel and reducing agent The metallic iron produced by such a furnace contains a relatively high proportion ofaustralia iron ore milling process plant for

milling process in mining concentrating the ore

are the milling process of gold Here is an Ancient Gold Ore Milling Process used in China in the 1800s We might use it again after WW3 At the time, 1890, the Author said "There is, of course, nothing for us to learn from this imperfect and rudimentary goldextraction process described here, which is doubtless destined to disappear ere long, before the progress of scientific mining, now The Iron Ore Industry has perhaps seen more varied and drastic changes in its approach to crushing and grinding in the last 5 years than any of the other mineral industries Multimillion ton per year plants have become common place Centralized control Iron Ore Crushing Grinding Controls 911 A variogram for iron grade after primary milling in the concentrating plant is presented in Fig 2 Application of variographic analysis to process data in LKAB iron ore concentrating and pelletizing enabled characterization of sampling systems through the entire value chain (not all sampling system evaluations are shown here) Evaluation of sampling systems in iron ore

What's the Process of Iron Smelting? Meetyou Carbide

Ironmaking methods mainly include blast furnace method, direct reduction method, smelting reduction method, etc the principle is that the reduced pig iron is obtained by physicochemical reaction of ore in a specific atmosphere (reducing substances Co, H2, C; appropriate temperature, etc)process mineralogy gold orEs and MinErals gold orE tyPEs Gold ores are commonly classified by the metallurgist into two major categories: freemilling and refractory ores Typically, freemilling ores are defined as those where over 90% of gold can be recovered by Establishing thE ProcEss MinEralogy of gold orEs an Iron Ore Milling Process Mohammad Tabesh, Ebrahim Azimi, Hooman AskariNasab Mining Optimization Laboratory (MOL) University of Alberta, Edmonton, Canada Abstract One of the most common techniques for studying a system’s behaviour, predicting its outputs and anticipating challenges along the way is simulationDiscrete Event Simulation of an Iron Ore Milling Process

iron ore fines grinding process netwerkoostkampbe

iron ore grinding machine in iron ore milling process from s As a professional and experienced manufacturer of mobile crusher,jaw crusher, cone crusher,impact crusher,ball mill,super fine mill and vertical mill Bowl Mill For Iron Ore Get price Study of Iron Ore Mixtures Behavior in the Grinding iron ore grinding machines,ballmillforiron ore grinding Iron ore grinding process Due to the various type of iron ore, the grinding process of iron ore is complicated Storage of iron ore can ensure the uniformity of material and continuous working of flour mill, it is also the important precondition of flour milling of iron oreiron ore grinding mill for milling process EscortIron ore, coke and lime are added to the top of a furnace Hot air is blown in from the bottom The furnace operates at a high temperature (around 1200°C) Iron ore reacts with carbon/coke to form iron metal and carbon dioxide The iron is tapped off at the bottom of the furnaceCrushing and milling Mining of mineral resources

Tue Ore Ball Mill Process Techner Engineers

iron ore ball mill for milling process Continuous Ball Milling Process Iron Ore Ball Mill for Ore Dressing Industry Ball Mill Appliion Ball mill is widely used in powdermaking production line which includes silie newtype building material cement refractory material fertilizer glass read more chromite ore milling process supplier krukkknlStrong magnetic iron ore belongs to freemilling mine, which can get highgrade iron concentrate with weak magnetic separation process With the improving demand of iron ore concentrate, Xinhai has speeded up the research and innovation of magnetic iron extraction process and magnetic separation equipment in recent years, and achieved Beneficiation of Iron, Iron Extraction Process, Iron Ore Iron ore mining equipment beneficiation process of the three most critical process crushing process milling process screening process and flotation process we are one of the leading manufacturer and exporter of mineral ore beneficiation plant and machines fabricated from superior quality,Joshua Hendy Iron Works Wikipedia,By the 1890s, the iron milling machine iron ore mining equipment

iron ore ball mill for milling process,iron ore mining

mobile stone crusher netherland,stone crushers manufacturers in malaysia,jaw crusher china supplier manufacturing,copper process equipment for gold ore mining iron ore ball mill for milling process,iron ore Iron Ore Cobbing Process What is Cobbing in iron ore Crushing Process what is Cobbing in iron ore Crushing Process Heavy Industry is a high tech company integrating R D production and distribution and provides crusher sand making grinding equipment mobile crushing station etc mature products and solutions used in aggregate mining and waste recyclingIron Ore Cobbing Process Ironmaking methods mainly include blast furnace method, direct reduction method, smelting reduction method, etc the principle is that the reduced pig iron is obtained by physicochemical reaction of ore in a specific atmosphere (reducing substances Co, H2, C; appropriate temperature, etc)What's the Process of Iron Smelting? Meetyou Carbide