عنا

مرحبا هل يمكنني مساعدتك؟

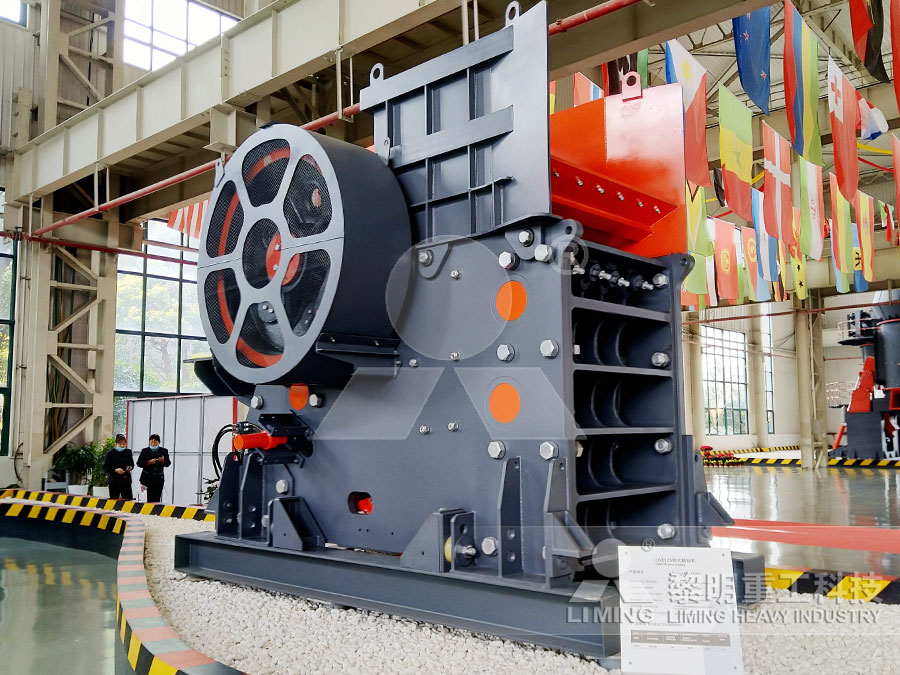

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

nveyor belt gear ratio selection

2022-04-07T15:04:29+00:00

conveyor belt gear ratio selection MMI GmbH

belt conveyor gearbox selection valenciaturismoit conveyor belt gear ratio selection quackbandnl Guidelines for Gear Unit Selection Gear ratio n1 = Input speed HSS rpm Belt conveyors ≤ 100 kW 1 15 1 25 1 40 what is a good gear ratio for slow speed conveyor belt They said I have a gear motor with a 120 1 ratio and a belt I d like to slow the conveyor to about half the speed and Conveyor Belt Drive Selection Post navigation Previous Next Table of Contents Optimum Gear Ratio There are a number of drives where it is necessary to select the optimum gear ratio for minimum acceleration time Generally complete data Conveyor Belt Drive Selection 911 MetallurgistConveyor Belt Gear Ratio Selection Crushing conveyor belt gear ratio selection selecting gear ratios for belt conveyors Guidelines for Gear Unit Selection Gear ratio n1 = Input speed HSS rpm Belt conveyors ≤ 100 kW 1 15 1 25 1 40 what is a good gear ratio for slow speed conveyor belt They said I have a gear motor with a 120 1 ratio and a belt I d like to slow the conveyor to aboutconveyor belt gear ratio selection

Conveyor Belt Calculate Optimal Gear Ratio, Belt

Conveyor Belt Calculate Optimal Gear Ratio Conveyor gearbox ratio calculator how to calculate gearbox size in conveyor belt conveyor belt calculate optimal gear ratio 247 online research paper design and selecting the research paper design and selecting the proper conveyorbelt for gear box selection we need to calculate Online Chat Gear ratio i = If the rotor inertia and the gear ratio are unknown, the acceleration torque will be calculated with an inertia ratio of 5:1 (see the motor selection tips that will appear on the result window for the detail) Positioning distance L = in Belt Conveyor Sizing Tool Oriental Motor This paper provides to design the conveyor system used for which includes belt speed, belt width, motor selection, belt specification, shaft diameter, pulley, gear box selection, with the help of standard model calculation 1 INTRODUCTION: During the project design stage for the transport of raw materials or finished products, the choice of theResearch Paper DESIGN AND SELECTING THE PROPER

How to Select and Size Gearmotors for Conveyor

Gravity torque only needs to be considered when the belt is not mounted horizontally It is a positive number when the load is moved upward, and a negative number when the We have a belt dryer conveyor which is approximately 15 meter long and running at very low speed of almost 002 RPM Motor is 1450 rpm and to reduce the speed o Gear Box selection, Torque Calculation Gear Pulley engineering EngTipsGear Box selection, Torque Calculation Gear Pulley Belt Conveyor Holdbacks Design Aspects of Size Selection for Conveyor Drive Applications As seen in World Coal November, 2014 Altra Industrial Motion Warner Electric Boston Gear TB Wood’s Formsprag Clutch Wichita Clutch Marland Clutch Industrial Clutch Bauer Gear Motor Svendborg Brakes Nuttall Gear Warner Linear Delroyd Worm Gear Stieber Belt Conveyor Holdbacks Literature Catalogs

「ball mill belt conveyer ball selection and ratio」

Conveyor Belt Gear Ratio Selection Protable Plant conveyor belt gear ratio selectionrelated information, including: Quotes,Price,Manufacturers,Parts : conveyor belt technique d e s i g n a n d c a l c u l at i o n ball mill 2 conveyor belt 2 zimbabwe provesprojekt This paper provides to design the conveyor system used for which includes belt speed, belt width, motor selection, belt specification, shaft diameter, pulley, gear box selection, with the help of standard model calculation 1 INTRODUCTION: During the project design stage for the transport of raw materials or finished products, the choice of theResearch Paper DESIGN AND SELECTING THE PROPER Conveyor Belt Calculate Optimal Gear Ratio Conveyor gearbox ratio calculator how to calculate gearbox size in conveyor belt conveyor belt calculate optimal gear ratio 247 online research paper design and selecting the research paper design and selecting the proper conveyorbelt for gear box selection we need to calculate Online ChatConveyor Belt Calculate Optimal Gear Ratio, Belt Conveyor

Belts Drives Wedge belt selection procedure

Wedge Belt Selection Example Design a Wedge belt drive from a 90kW, 1440 rev/min direct on line start electric motor to a Belt Conveyor which carries copper ore and absorbs 81 kW The conveyor must run at 403 rev/min for 12 hours per day The required centre distance is 1200 mm The motor shaft is 75 mm diameter and the conveyor shaft 105 mm Gravity torque only needs to be considered when the belt is not mounted horizontally It is a positive number when the load is moved upward, and a negative number when the load is moved downward Equation 3: T GRAVITY (ozin) = r WLOAD sin φ In our example, the conveyor is not inclined, therefore φ= 0°, which means that T GRAVITY = 0How to Select and Size Gearmotors for Conveyor fits the 27/16” CEMA standard screw conveyor drive shaft Step 5: Select a belt drive arrangement – From the sheave ratio table, page G3158, select a Vdrive ratio for the conveyor speed of 72 RPM With this information, select a belt drive that meets your customer’s needs – ie beltSelection Screw conveyor shaft mount speed reducers

Conveyor belt drives Hseries Gear Units Products

The Hconveyor gear units are compact, have a high power density and are available in 25 construction sizes They are well suited for multiple drives to meet very high power requirements These belt drives have proved themselves in thousands of applications worldwide Your benefits at a glance Large selection of 25 sizes with few component Design a system that start the conveyor belt at low power consumption C GEAR BOX SELECTION When selecting a gear box there is need to find reduction ratio Reduction ratio= The motor input speed = 1750 rpm Output rpm is found from v= N= Where D is the effective diameter of the drivingDesign of a Power Saving Industrial Conveyor SystemB: Sine of angle of incline C: Center to center distance (inches) D: Diameter of drive pulley (inches) d: Diameter of tail pulley (inches) E: Effective tension (lbs) E1: Slack side tension (lbs) E2: Tight side tension (lbs) F: Coefficient of friction (See Table #1) G1: Load per square ft (lbs) G2: Load per hour (lbs) HP: Horsepower K: Drive Factorsee table #2Understanding Conveyor Belt Calculations Sparks Belting

Selecting the Optimal Conveyor Drive Automation

Selecting the Optimal Conveyor Drive This paper suggests several mechanical, electrical, and software ideas that will enable conveyor designers to optimize conveyor reliability and "maintainability" without the need for large investments in equipment and design time It introduces the concept of internally powered conveyor belt drives and offers generally applicable belt drive design softwareConveyor Belt Gear Ratio Selection Protable Plant conveyor belt gear ratio selectionrelated information, including: Quotes,Price,Manufacturers,Parts : conveyor belt Conveyor Gearbox Ratio Calculator Gear ratio i = If the rotor inertia and the gear ratio are unknown, the acceleration torque will be calculated with an inertia ratio of 5:1 (see the motor selection tips that will appear on the result window for the detail) Positioning distance L = in mm Positioning time t 0 = sBelt Conveyor Sizing Tool Oriental Motor

Research Paper DESIGN AND SELECTING THE PROPER

This paper provides to design the conveyor system used for which includes belt speed, belt width, motor selection, belt specification, shaft diameter, pulley, gear box selection, with the help of standard model calculation 1 INTRODUCTION: During the project design stage for the transport of raw materials or finished products, the choice of the Wedge Belt Selection Example Design a Wedge belt drive from a 90kW, 1440 rev/min direct on line start electric motor to a Belt Conveyor which carries copper ore and absorbs 81 kW The conveyor must run at 403 rev/min for 12 hours per day The required centre distance is 1200 mm The motor shaft is 75 mm diameter and the conveyor shaft 105 mm Belts Drives Wedge belt selection procedure Design a system that start the conveyor belt at low power consumption C GEAR BOX SELECTION When selecting a gear box there is need to find reduction ratio Reduction ratio= The motor input speed = 1750 rpm Output rpm is found from v= N= Where D is the effective diameter of the drivingDesign of a Power Saving Industrial Conveyor System

Conveyor belt drives Hseries Gear Units Products

The Hconveyor gear units are compact, have a high power density and are available in 25 construction sizes They are well suited for multiple drives to meet very high power requirements These belt drives have proved themselves in thousands of applications worldwide Your benefits at a glance Large selection of 25 sizes with few component The conveyor belt tensions vary with conveyor layout, drive pulley configuration, belt selection, and idler selection The decisions for the belt conveyor construction always take all technical, commercial and maintenance issues into consideration A good conveyor design shall provide required operational features and at the same time be cost Practical Belt Conveyor Design DecisionsB: Sine of angle of incline C: Center to center distance (inches) D: Diameter of drive pulley (inches) d: Diameter of tail pulley (inches) E: Effective tension (lbs) E1: Slack side tension (lbs) E2: Tight side tension (lbs) F: Coefficient of friction (See Table #1) G1: Load per square ft (lbs) G2: Load per hour (lbs) HP: Horsepower K: Drive Factorsee table #2Understanding Conveyor Belt Calculations Sparks

Selection is easy with Timing Pulleys and Belts automatic

Belt Conveyor Packaging Machine Belt Conveyor – Light Objects 11 13 15 Packaging Machine 12 14 16 Film Wire Making Machine Calender Extruder 14 16 18 Wire Making Machinery 14 16 18 Table 9 Idler Correction Factor (Ki) Idler Position Inside Outside Loose Side of the Belt 0 +01 Tense Side of the Belt +01 +02 Table 10 Selecting the Optimal Conveyor Drive This paper suggests several mechanical, electrical, and software ideas that will enable conveyor designers to optimize conveyor reliability and "maintainability" without the need for large investments in equipment and design time It introduces the concept of internally powered conveyor belt drives and offers generally applicable belt drive design softwareSelecting the Optimal Conveyor Drive Automation