عنا

مرحبا هل يمكنني مساعدتك؟

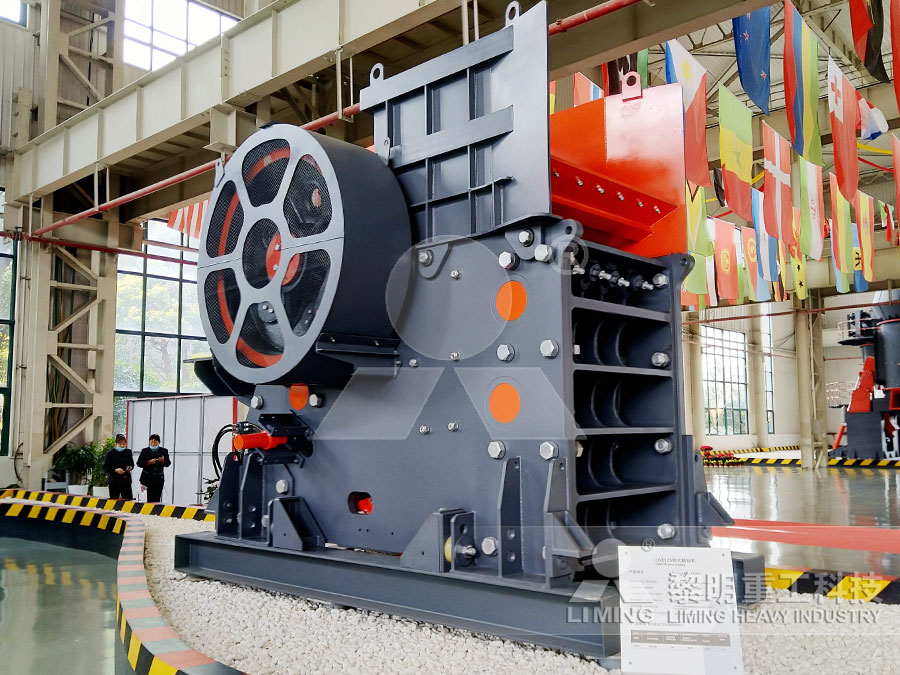

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pper lead flotation separation

2022-03-01T03:03:57+00:00

Copper Lead Concentrate Separation 911 Metallurgist

The separation of copperbearing from zinc sulphides is effected by twostage selective flotation, the zinc minerals being depressed and the copper minerals brought up in the first stage with reagents similar to those required in the lead flotation section of a leadzinc plant; the zinc sulphides are floated in the second stage in the ordinary way The ores treated by this process are mainly those To achieve this copper/lead separation, bulk flotation is performed with depressants to control sphalerite and pyrite Cyanide was used in the bulk rougher as it will also be used in the reverse Rougher testing indicated that 10 to 50 g/tonne How to Separate Copper from Lead by Cu Depression Separation of copper and lead minerals present in the industrial flotation concentrates by flotation in the presence of either potato starch, guar, dextrin DBM or dextrin Fluka as the depressant of lead minerals and 50g/t KEtX as well as 50 g/t αterpineolRemoval of lead minerals from copper industrial

separation by flotation of copper lead zinc sulphides

The froth flotation technology of copper, lead and zinc sulfide ore is very rich A certain copper, lead, zinc and sulfur ore in Tibet is used for partial mixed flotation process It is mixed with medium ore for regrinding, and activated carbon is used as the agent for separation The combination of CMC, sodium sulfite and sodium silicate isCopperLeadZinc ores The CuPbZn separation process is among the most challenging flotation separations primarily because the first step must entail bulk flotation of the two most readily floatable minerals with these two minerals separated in a differential flotation stage In this case, as a general rule because both copper and lead minerals CopperLeadZinc ores Danafloat In general terms, the most common treatment methods include (a) sequential copper/lead/zinc flotation, and (b) bulk copper/lead flotation followed by copper/lead separation and zinc flotation Another method known to be used in industrial practice is bulk copper/lead/zinc flotation, followed by separation of the individual mineralsDevelopment and introduction of a new copper/lead

Copper Lead Separation with Activated Carbon

Geco Concentrator Metallurgy The testwork was aimed at improving selectivity in samples of a copper/lead ore from the GECO mine located at Manitouwadge, Ontario The basic components of the flotation circuit involve the combination of a differential circuit for copper/zinc separation and a bulk/selective circuit for copper/lead separation The results demonstrated that the favorable size fraction for the coppergoldlead separation flotation was −74 + 20 μm The classical firstorder model was considered as the optimum model to adapt to the coppergoldlead separation flotation process in this investigationEffects of particle size on flotation performance in the So, applying the leadcopper separation technique is possible separate bismuth and copper too There are several methods for leadcopper separation But, perhaps, the more common is employing NaCN as depressant for chalcopyrite, and LeadBismuth Flotation 911 Metallurgist

Lead Zinc Separation by Flotation Froth Flotation

Some of the metals that can do the job are copper and lead At a pH between 89 lead can activate sphalerite to cause it flotation So the reason is during the flotation of the two there may be lead re dissolution from galena which may activate sphalerite to cause it flotation It may best if you are doing bulk flotation of the twoCopper Lead Concentrate Separation 01/10/2015 The ways to obtain successful Separation of Copper and Lead into individual Concentrates, several process approaches can be examined; bulk copperlead flotation with a reverse flotation stage depressing copper, the same bulk flotation with a reverse flotation to depress lead and a sequential copperleadzinc flotation circuit as well as a simple separation by flotation of copper lead zinc sulphides processes Article A Novel Technology for Separation Copper, Lead and Zinc in Flotation Concentrate by Oxidizing Roasting and Leaching Qian Zhang 1,2, Qicheng Feng 1,2,*, Shuming Wen 1,2, Chuanfa Cui 3 and Junbo Liu 1,2 1 Faculty of Land Resource Engineering, Kunming University of Science and Technology, Kunming , China; zqian9865@163 (QZ); shmwen@126 A Novel Technology for Separation Copper, Lead and

(PDF) A Novel Technology for Separation Copper,

The flotation concentrate contained 779% Cu, 2200% Pb, 481% Zn, 824% S, and 1215% CaO; copper sulfide accounted for 7697% of the copper, lead sulfide for 2555% of the lead, and zinc sulfide Copper lead mixmining flotation With the condition of mixing slime slurry, the PH reaching around 75, having the Ty 1 and zinc sulfate as inhibitors of sphalerite, iron sphalerite, having The Introduction of Flotating Process about Copper Abstract:s: An experimental research was conducted for a copperlead polymetallic sulfide ore with beneficiation technology of copperlead bulk flotation followed by copperlead separation.Sulfuric acid was used as regulator, and environmental protection agent ZJ201 was used as lead inhibitor, Not only can the copperlead concentrate be separated and recovered effectively, but also the 新型环保抑制剂在某铜铅精矿浮选分离中的应用Application

Enhancing flotation separation of chalcopyrite and

Qin, W et al Utilization of polysaccharides as depressants for the flotation separation of copper/lead concentrate Int J Mining Sci Technol 23, 179–186 (2013) The results were found to be very promising for recovering copper from dilute aqueous ammoniacal leachates of lowgrade sulphidic copper–lead–zinc tailings by ion flotation Full reference paper Xanthopoulos, P, Kalebić, D, Kamariah, N et al Recovery of Copper from Ammoniacal Leachates by Ion Flotation J Sustain Metall (2021)Selective recovery of copper from ammoniacal The ore is the oxide ore of Copper lead and zinc, The ore has high Oxidation rate of Pb,nearly 50% which contains 356% of Pb,386% of Zn,0209% of CuSeparation of Copper, Lead, and Zinc with

国土资源工程学院

(6) Sulfidization flotation of copper, lead and zinc oxide minerals, 中国有色金属学会, 青年科技论坛优秀报告奖, 2018 (7) 低品位复杂铜矿资源高效利用关键技术及应用, 中国有色金属工业协会, 科技进 The flotation machine is mainly used to sort nonferrous metals such as copper, zinc, lead, nickel, gold, etc, and ferrous metals and nonmetals The classification of flotation machine mainly includes SF type flotation machine, GF type flotation machine, BSK type flotation machine, XJK series flotation machineDifferences and Applications of Magnetic Separation processes Article A Novel Technology for Separation Copper, Lead and Zinc in Flotation Concentrate by Oxidizing Roasting and Leaching Qian Zhang 1,2, Qicheng Feng 1,2,*, Shuming Wen 1,2, Chuanfa Cui 3 and Junbo Liu 1,2 1 Faculty of Land Resource Engineering, Kunming University of Science and Technology, Kunming , China; zqian9865@163 (QZ); shmwen@126 A Novel Technology for Separation Copper, Lead and

CopperLeadZinc

CuPb Froth Flotation Guidance This article will introduce the froth flotation of copperlead ore from flotation inhibition separation method, flotation process and reagent system Click to know moreA Novel Technology for Separating Copper, Lead a In this work, oxidizing roasting was bined with leaching to separate copper, lead, and zinc from a concentrate obtained by bulk flotation of a lowgrade ore sourced from the Jiama mining area of Tibet The flotation concentrate contained 7 79% Cu, 22 00% Pb, 4 81% Zn, 8 24% S, and 12 15% CaO; copper sulfide accounted for 76 97% of the copper Separation of copper from lead Manufacturer Of The test ore is a kind of relatively high grade of sulphide copperlead ore, the difficulties of test is the effective separation of copper and lead, the lead grade of 1308% and copper grade of 133% in comprehensive core sample After the exploring test of principle flow sheet, the flotation process of depress lead and float copper is usedSeparation Test of CopperLead Ore from Guangxi

The Introduction of Flotating Process about Copper

Copper lead mixmining flotation With the condition of mixing slime slurry, the PH reaching around 75, having the Ty 1 and zinc sulfate as inhibitors of sphalerite, iron sphalerite, having Abstract:s: An experimental research was conducted for a copperlead polymetallic sulfide ore with beneficiation technology of copperlead bulk flotation followed by copperlead separation.Sulfuric acid was used as regulator, and environmental protection agent ZJ201 was used as lead inhibitor, Not only can the copperlead concentrate be separated and recovered effectively, but also the 新型环保抑制剂在某铜铅精矿浮选分离中的应用Application Qin, W et al Utilization of polysaccharides as depressants for the flotation separation of copper/lead concentrate Int J Mining Sci Technol 23, 179–186 (2013)Enhancing flotation separation of chalcopyrite and

EVALUATION OF ORGANIC CARBON SEPARATION FROM

underground copper, zinc and lead mines in the world Copper and leadzinc ores are mined and processed separately The final concentrate produced in Mt Isa mine's ore concentrator plants during standard flotation would have been heavily contaminated by naturally floating carbonate pyrite, talk and carbon shale Due to this fact a pre (6) Sulfidization flotation of copper, lead and zinc oxide minerals, 中国有色金属学会, 青年科技论坛优秀报告奖, 2018 (7) 低品位复杂铜矿资源高效利用关键技术及应用, 中国有色金属工业协会, 科技进 国土资源工程学院 The flotation machine is mainly used to sort nonferrous metals such as copper, zinc, lead, nickel, gold, etc, and ferrous metals and nonmetals The classification of flotation machine mainly includes SF type flotation machine, GF type flotation machine, BSK type flotation machine, XJK series flotation machineDifferences and Applications of Magnetic Separation